TCEQ grants Collier Materials permit

By Lew K. Cohn

Managing Editor

The Highlander

Nearly five months after an informational hearing held in Marble Falls, the Texas Commission on Environmental Quality has given final approval to an air quality permit for a Collier Materials Inc. 300-ton enclosed rock crusher in Tobyville.

Those opposed to the permit have until April 2 to file a motion to overturn Collier's 10-year air quality permit with the TCEQ Office of the Chief Clerk in Austin, though any such motion would have to explicitly indicate why the TCEQ should review the permit decision.

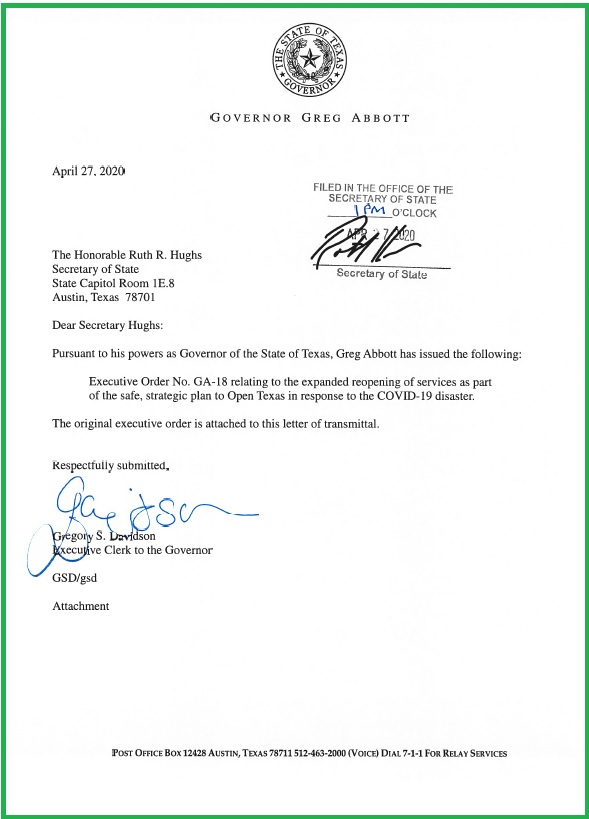

TCEQ executive director Richard A. Hyde PE signed air quality permit 146397L001 on March 9, TCEQ chief clerk Bridge Bohac said in a letter sent to people who attended last October's meeting at the Holiday Inn Express in Marble Falls.

Bohac wrote affected parties may also request a “judicial review” of the executive director's approval, under Texas Health and Safety Code § 382.032. However, any such petition for judicial relief must be filed in a Travis County district court within 30 days of the effective date of the approval, or by April 8.

“Even if you request judicial review, you still must exhaust your administrative remedies, which includes filing a motion to overturn,” Bohac wrote.

According to the executive director's response to public comments on Collier's permit application, staff members on TCEQ’s Air Dispersion Modeling Team reviewed all modeling procedures, methodology, predictions and results, which were “determined to be acceptable.”

“It was determined that based on the potential predicted concentrations reviewed by the Executive Director’s staff, adverse short- or long-term health effects for the general public, including sensitive subgroups such as children, the elderly, or persons with preexisting medical conditions; animal life; crops; vegetation; or buildings are not expected as a result of exposure to the proposed emissions,” the document stated. “In addition, adverse health effects are not expected for persons living on or visiting nearby properties.”

During the Oct. 24, 2017, informational meeting, a representative of the Collier plant said his company could be finished working their 4601 Ranch-to-Market Road 1980 site “within two to three years” if their air quality permit for the crusher was approved. The new crusher is similar to one operating currently at the company's Llano County plant.

"We project that we can, in two to three years, be out of there and have all of that rock crushed in no time," Collier Materials Inc. vice president Kevin Collier said. "It would take us 10 years to be finished without this crusher. This type of crusher, you can stand beside it and not even know it is running. It is an enclosed crusher, not an open one, and it doesn't produce dust like an open crusher.

“Our reserve is 90 percent depleted there and we have been at that site for seven years. There is no way we can be there more than three more years.”

Collier also indicated at the meeting the company will not be trucking in material from any other site to the Tobyville location, but will only be using it to crush oversized material already present.

"We're only going to crush material that is already on site. Once we are done, we are done,” he said.

During the meeting, residents disputed assertions by Collier that the new equipment at the existing site would not cause air pollution and questioned TCEQ staff about how they would police infractions by the company. Some of the biggest concerns from residents were about respirable crystalline silica, a particulate matter which has a PM classification of four microns or less.

In his response to public comment, however, Hyde noted the EPA “has not classified PM4, or silica, as a hazardous air pollutant or criteria pollutant.” He also noted the primary contaminants at the proposed plant were expected to be PM10 and PM2.5, which are particulates at 10 microns or less and those at 2.5 microns or less.

Control measures will include applying water at the entrance and exit of all crushers and at all transfer points for non-saturated material.

“In addition, stockpiles, active work areas, loading areas, in-plant roads, parking areas, and other traffic areas must be sprayed with water upon detection of visible emissions of PM,” Hyde wrote.

Collier is also requireed to observe minimum property line setbacks to create a buffer zone and to resstrict visible fugitive emissions from leaving the property.

“As part of the permit evaluation process, the permit reviewer audits all sources of air contaminants at the proposed facility, assures that the facility will be using the best available control technology (BACT) applicable for the sources and types of contaminants emitted, and determines that no adverse effects to public health, general welfare, or physical property are expected to result from a facility’s proposed emissions,” Hyde wrote. “The TCEQ cannot deny a permit if the applicant demonstrates that all applicable statutes, rules, and regulations will be met.”